Porcelain Insulator News

by Jack H. Tod, NIA #13

Reprinted from "INSULATORS - Crown Jewels of the Wire", July 1979, page 24

FOREIGN INSULATORS

Flash! Great news! Marilyn Albers

(NIA #541) of Houston, Texas has stepped forward to volunteer as a clearing

house for information on foreign insulators.

In the October 1978 column (page

32), I pointed up the ever increasing interest in collecting foreign insulators

and lamented the fact that the Crown Jewels staff just couldn't answer all the

questions received on foreign insulators. It seemed like a futile try, but I

asked if there was anyone out there who would volunteer to serve as a

"clearing house" for foreign items. But, alas! A miracle. Enter

Marilyn.

Marilyn pondered the idea for some time of accepting this challenging

task, knowing full well that it would mean quite a dent in her spare time. When

she made the firm decision to tackle it, the wheels were set in motion for her

to initiate a regular feature column on foreign insulators in CJ that should be

great news for many of our readers.

It's hard to find any collector so eminently

qualified for this task as Marilyn is. Foreign insulators are her first love,

and she has an extensive collection of them. The big plus though is that she

periodically visits foreign countries in her capacity as a tour chaperon, and

this affords an opportunity to gather accurately attributed insulator specimens

themselves and possibly information from some of the foreign manufacturers of

insulators.

I and others involved in gathering information on insulators will

certainly assist and encourage Marilyn in any way we can, and hopefully each CJ

subscriber will do likewise. Her work could lead to a compilation of insulator

styles and markings which would serve to answer many questions which were

formerly puzzlers to us.

We will never be able to learn as much about foreign

insulators as we have about U.S. glass and porcelains, yet Marilyn's work may

lead to a storehouse of information which will make it much more meaningful and

fun to collect the very interesting insulators we've seen from foreign lands. It

will be considerable work, but knowing that it will help so many fellow

collectors is a reward in itself. I want to thank Marilyn for her interest in

this project and to wish her the best of luck in its undertaking.

Jack

Dear Jack:

While my collecting specialty is glass insulators, I read your

regular column on porcelain insulators in Crown Jewels. Enclosed is an article

from the Jan-Feb 1979 issue of Solid State Power Conversion magazine, and it

describes the development of a new insulating material, "Polysil".

Thought you might find this article interesting.

Niels Lahr, NIA #726

Rockledge,

FL

- - - - - - - - - -

Any such new developments should be of interest to all insulator collectors,

so we'll give you the high points on it.

The new material is "Polysil"

(EPRI trademark), and it was developed by Westinghouse Electric Corp. under a

contract with the Electrical Power Research Institute. Polysil is a derivative

of polymer concrete developed in the 1960's and which has since been used

successfully in Bureau of Reclamation projects for some time now. The polymer

concrete is a mixture of aggregates and organic binder and has six to eight

times the compression strength of conventional concrete and is better at

resisting waterflow erosion.

Polysil is a combination of silica or ground rock,

organic binder and reinforcing fibers. After thorough blending, the mixture is

poured into a vibrating mold in a vacuum chamber. After about 3 minutes, the

compaction is complete, and it is allowed to gel and cure for about an hour.

The

material has several economical, logistical and technical advantages over

porcelain. Plants for its manufacture would be relatively simple and could be

strategically located, even to the point of being operated by individual

utilities for making insulators required there. Polysil could be made at less

than half the cost of porcelain, mainly because firing isn't required and

because integral metallic parts can be cast in place instead of being attached

to a separate insulating body as is necessary with porcelain insulators.

All

forms of conventional insulators (pin types, bushings, posts, etc.) have been

made and are being extensively tested by several utilities under varying

conditions. The utility industry is very much aware of the potential for the

Polysil insulators, but there is still the question of its durability and

longevity. [They evidently still remember the disaster 60 years ago when the

Jeffery-Dewitt suspension insulators were widely used before they were proven

reliable and subsequently failed in relatively large numbers.]

There probably

will never be more than a gradual acceptance and use of Polysil line insulators,

but their use will come about in time. We'll keep our ear to the ground for the

first general use of Polysil pin type insulators and will report it at the time.

Jack

There's something quite new on the insulator front from PLASTIGAGE

CORPORATION, 915 E. South St., Jackson, Mich. 49204. Richard N. Essig, Director

of Research & Engineering, sent data sheets an their new "Hether-Lite"

(trademark) units designed and developed by Mr. Essig and now being marketed by

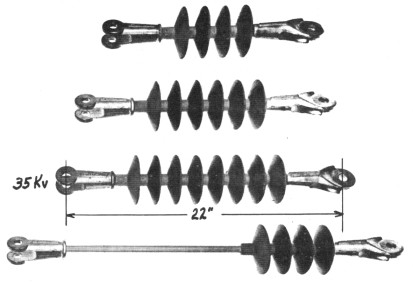

Plastigage. The cataloging lists a total of 12 styles and ratings thus far -- 15

Kv, 25 KV, 35 Kv and 46 Kv ratings in each of three styles: Deadend/suspension,

standoff, and standoff insulator. Typical units are illustrated in the cut

below; the top three are suspension types, and the bottom one is an extension

insulator.

Even though these Hether-Lite insulators are a new development of

Plastigage Corp., the company has been making polymeric products since 1955. The

design is one of simplicity and utility -- a 5/8" fiberglass rod, polymer

plastic skirts, aluminum or galvanized iron and fittings. Typical applications

are illustrated in the following cuts.

Among the benefits claimed for

these insulators (vs. the comparably rated porcelains) are: Bullet resistant,

high tensile strength for their rating size, lightness of weight to reduce

handling, storage and shipping costs. These claims are similar to those made for

other plastic line insulators now on the market in competition with porcelain.

It's interesting to me that the data sheets fail to mention that these insulator

types do not require the expenditure of large quantities of natural gas for

firing as porcelain insulators do (an "energy saver" design). But

then, I suppose, the porcelain companies could also point out that their items

don't require quantities of crude oil for their manufacture as the plastic

products do!

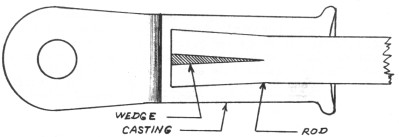

I couldn't help but be distracted by the illustration on the data

sheets of the patented wedge method of retaining the fiberglass rod in the end

fittings. This is shown by my sketch below. As the rod is pushed into the end

fitting, the wedge separates and squeezes the rod material against the outwardly

beveled interior walls of the hole in the cap.

A mastic-epoxy sealer is applied

to the rod end before it is inserted, and when the assembly is mechanically

pulled after the rod is inserted, a uniform bond is achieved between the rod and

cap. Clever! Why can't I think of things like that?

Readers connected with

utility companies who might be interested in these new insulators should contact

Plastigage at the above address for data sheets. Incidentally, Mr. Essig was

formerly associated with Reliable Electric Company, Franklin Park, Ill., and he

developed their plastic pin type insulators which we reported and described in

the October 1978 porcelain column.

Jack

Dear Jack:

I recently thought of

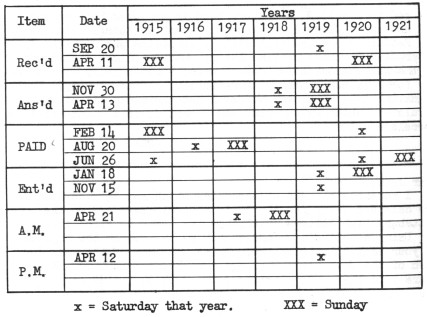

something which may help us decipher the calendar years for the "date

control" markings on the Pittsburg High Voltage insulators (ie. "FEB

14 PAID" etc.).

Using a periodic calendar such as the one in the appendix

of your book "Electrical Porcelain", the day of the week for each of

the date stamp markings can be determined for the years 1916-1921. For instance,

the "NOV 30 Ans'd" listed in your "Porcelain Insulators Guide

Book" falls on Sunday in 1919 (and is a Saturday in 1918). Thus, the year

1919 might be eliminated for the "Ans'd" code if it is assumed there

was no production on Sunday (a safe assumption?).

If enough of the date

control markings could be rounded up, it might be possible to determine the

actual years for each code through a process of elimination. I'll leave it up to

you to decide whether or not this method might work.

Matt Grayson, NIA #387

Roslyn, NY

- - - - - - - - -

Dear Matt:

A super idea! It may or may not work, but it's better than

nothing, and it would be fun to give it a try.

There are several considerations

regarding elimination of Sunday and Saturday dates. There may have been occasion

for Sunday work during the war years 1916-1918, even though domestic line

construction was probably at a reduced level during those years. Certainly

Sunday work would have been improbable during the depressed years 1919 through

1921.

Incuse markings are usually applied at the green-trimming stage, and that

is usually done about 24 hours after the insulators are press formed. It is not

abnormal for a shift to trim on Saturdays insulators pressed the preceding day,

so it may be unreliable to count out Saturday dates. (Most, if not all, date

control markings I can recall have been on trimmed insulators and not on those

made in parting-type molds requiring no trimming.)

As a starter, I've shown in

the following table Saturday and Sunday years for the date control markings I've

been able to dig out.

I've had numerous others reported in letters, but it is a

hopeless case to go through about 50" of letter files to recover the info

on them.

HELP!

Now, to attempt a solution to the date riddle

discussed above, we need all our readers to report any Pittsburg date control

markings they have which aren't listed above. Just jot them down on a postcard

and send them to me -- while you're thinking of it. Please?

Please report only

those which are unmistakable as to the code element and exact date. Please note

on the card if you are not 100% certain of the date. You might also note the

U-number of the insulator and whether it has turned side groove or was made in a

parting-type mold not requiring trimming (a mold line all the way up the side).

This project has a chance for success only if each of you readers will help out

by sending in the information we need. Maybe as few as a dozen more marking

dates in the table above would give a solution to the riddle. If this leads to

cracking the Pittsburg date coding, a big thank you to Matt for his inspired

idea.

Jack

Dear Jack:

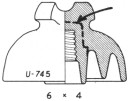

We have had this Pittsburg U-745 in our collection for

about three years and always wondered whether or not it was a glaze weld. So we

took it to the lapidary saw artist and had it sectioned in half. It is a glaze

weld, and we are sending to you this half of it for your reference.

Emma &

Tony Almeida, NIA #979 & 1166

Shrewsbury, Mass.

- - - - - - - - - -

This was the Pittsburg #69

(circa 1910-1920). The only Pittsburg catalog I have, or have seen, is the

undated No. 3 catalog, and the #69 was shown there as a one-piecer. This is

notwithstanding the fact that some insulators in that catalog are obviously

glazewelds but not drawn as such. It stands to reason this insulator (and

similar ones by Locke) probably originated as glazewelds, and this specimen is

the proof of the pudding on that count.

The Pittsburg U-745 specimens I've seen

just don't show any outward trace of being glazewelds, so many thanks to Emma

& Tony for settling the question for us.

Jack

|